APPLICATION

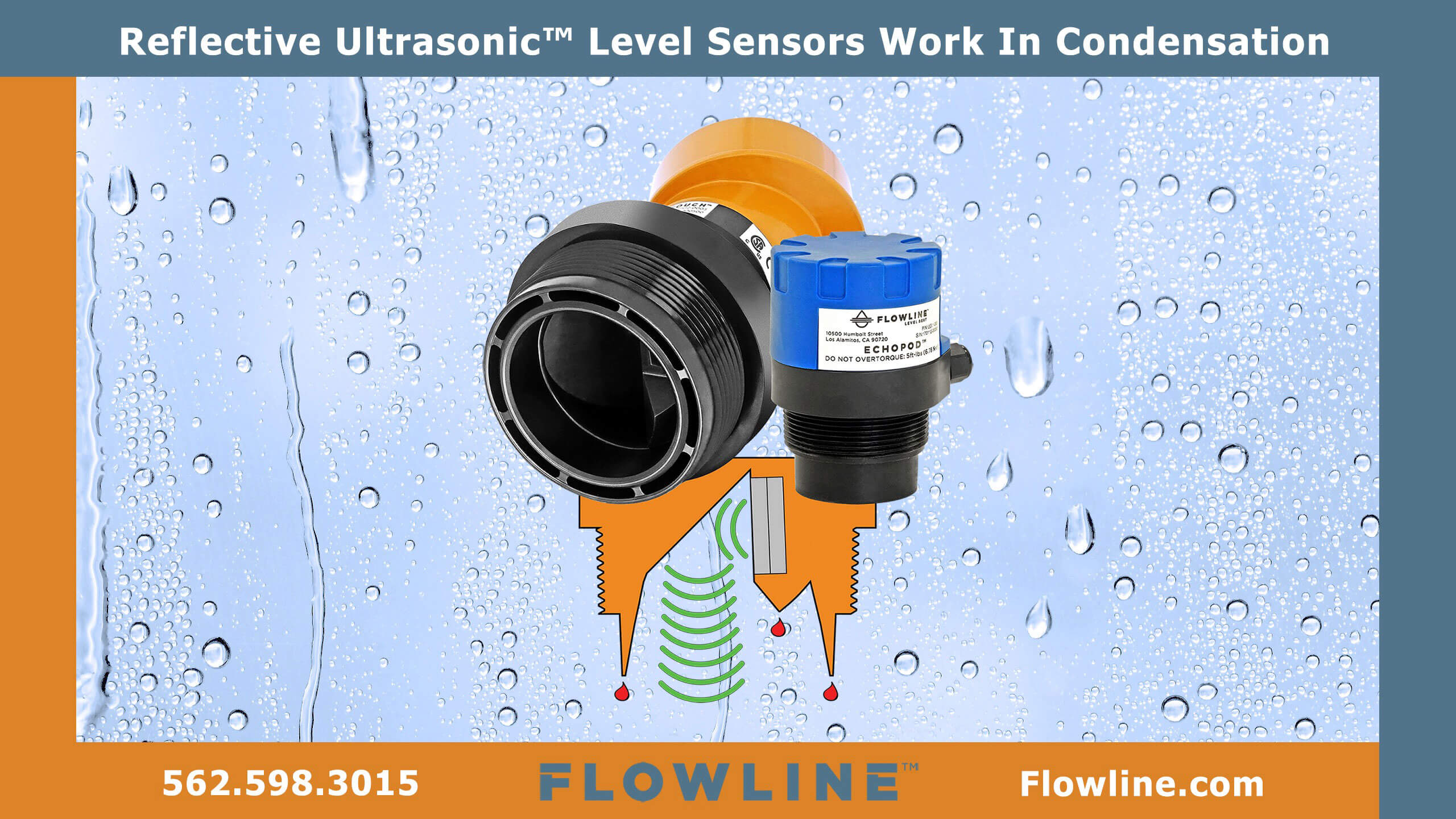

The general purpose reflective ultrasonic multi-function level transmitter provides continuous level measurement up to 9.8’ (3m) with a 4-20 mA analog signal output and four relays, and is configured via our WebCal software. The non-contact liquid level sensor features our proprietary Reflective Technology™ that delivers reliable level measurement in condensing environments. Each relay can be configured for alarm, automatic fill or empty functions. Select this sensor for small tanks with non-foaming and mildly vaporous media such as chemicals, water, wastewater and oil. Typical applications include day tank, IBC or drum, cooling tower, skid or machine, process tank and waste sumps.

FEATURES

- Offered in 1.5m (4.9’) and 3m (9.8’) measurement ranges

- Fail-safe diagnostics with selectable relay and signal outputs

- Narrow 2” (5cm) beam width for applications with limited space

- Corrosion resistant PVDF transducer and compact PP enclosure

- Short 1.5” (3.8cm) dead band maximizes tank filling capacity

- Automatic temperature compensation from -40º to 80º C.

- Four programmable relays with embedded level control logic

- 1 pump or valve with 3 alarms

- 2 pumps lead-lag with 2 alarms

- 2 pumps duplexing with 2 alarms

- 4 independent switch point alarms

REFLECTIVE

Condensation is the most common variable in liquid level applications. Condensation attenuates the acoustic signal of ultrasonic sensors with horizontal transducers, weakening their signal strength and signal to noise ratio by up to 50%, and substantially reducing their measurement reliability. At the core of Reflective Technology™ is a simple fact. Unlike flat horizontal surfaces, significant water droplets cannot adhere to smooth vertical surfaces. By orienting the transducer vertically, condensation runs off the transducer and does not affect sensor performance. The unimpeded transmit and receive signals are redirected to and from the liquid off a 45º reflector, delivering reliable level measurement. Thanks gravity.

Reflective Transducer

Reliable Measurement

Horizontal Transducer

Signal Attenuation

PRICING

| P/N | Description | From | |

|---|---|---|---|

|

UG01-0001-40 | GP ultrasonic level sensor, 1.5m (4.9′) range, 2″ NPT, 4-20 mA, 4 relays, w/o Fob | $580.00 |

| UG01-0001-41 | GP ultrasonic level sensor, 1.5m (4.9′) range, 2″ NPT, 4-20 mA, 4 relays, w/Fob | $645.00 | |

| UG01-0011-40 | GP ultrasonic level sensor, 1.5m (4.9′) range, 2″ G, 4-20 mA, 4 relays, w/o Fob | $585.00 | |

| UG01-0011-41 | GP ultrasonic level sensor, 1.5m (4.9′) range, 2″ G, 4-20 mA, 4 relays, w/Fob | $655.00 | |

|

UG03-0001-40 | GP ultrasonic level sensor, 3m (9.8′) range, 2″ NPT, 4-20 mA, 4 relays, w/o Fob | $660.00 |

| UG03-0001-41 | GP ultrasonic level sensor, 3m (9.8′) range, 2″ NPT, 4-20 mA, 4 relays, w/Fob | $725.00 | |

| UG03-0011-40 | GP ultrasonic level sensor, 3m (9.8′) range, 2″ G, 4-20 mA, 4 relays, w/o Fob | $665.00 | |

| UG03-0011-41 | GP ultrasonic level sensor, 3m (9.8′) range, 2″ G, 4-20 mA, 4 relays, w/Fob | $730.00 |

COMPATIBLE ACCESSORIES

DOCUMENTATION

SPECIFICATIONS

Range: UG01: 1.5” to 4.9’ (3.8cm to 1.5m), UG03: 4” to 9.8’ (10.1cm to 3m)

Accuracy: UG01: 0.125” (3mm), UG03: ± 0.2% of range

Resolution: UG01: 0.019” (0.5mm), UG03: 0.039” (1mm)

Dead band: UG01: 1.5” (3.8cm), UG03: 4” (10.1cm)

Beam width: 2” (5cm)

Configuration: WebCal® PC Windows® USB® 2.0

Memory: Non-volatile

Supply voltage: 14-28 VDC

Max. consumption: 0.5W

Loop resistance: 500 ohms @ 24 VDC

Signal output: 4-20mA, two-wire

Signal invert: 4-20mA or 20-4mA

Signal fail-safe: 4mA, 20mA, 21mA, 22mA, hold last

Contact type: (4) SPST relays

Contact rating: 60 VA, 1A maximum

Contact fail-safe: Open, closed, hold last

Contact hysteresis: Selectable

Process temp.: F: -40º to 176º, C: -40º to 80º

Temp. comp.: Automatic

Ambient temp.: F: -31º to 140º, C: -35º to 60º

Pressure: 30 psi (2 bar)

Enclosure rating: Type 6P (IP68)

Encl. material: Polypropylene

Transducer type: Reflective

Transducer mat.: Polyvinylidene fluoride

Cable jacket mat.: Polyurethane

Cable type: 9-conductor, shielded

Cable length: 48” (1.2m)

Process mount: -0001: 2” NPT, -0011: 2” G

Mount gasket: -0001: N/a, -0011: Viton®

Classification: General purpose

Approval: UL 61010-1

Compliance: CE, RoHS

CONFIGURATION

WebCal® software is a PC utility program that enables users to easily configure and test compatible Flowline level sensors to their measurement and control requirements. Download your free copy.

PRODUCT SELECTION

If you want help in selecting a sensor for your application, please submit a Level Questionnaire. An engineer will review your requirements and suggest a product solution via email.

LEVEL TECHNOLOGY

AWARD WINNER

Processing Magazine selected Flowline to receive their Breakthrough Product of the Year Award for our EchoPod and EchoTouch reflective ultrasonic sensors that provide reliable level measurement in condensing environments. See how.