|

|

|

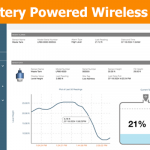

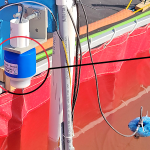

When an Ohio metal manufacturer needed reliable level detection and switching of their parts washing machine, they turned to Flowline. They fabricate parts to order and the last step in their process is washing. During which, baskets are placed into a washing machine that sprays and rinses the parts in a solution of hot water, degreaser and acid. The solution passes through a filter and returns to the recirculation tank that feeds the sprayers. There the controls engineer wanted to replace the prior metal float level switches explaining, “Despite the filtering, the recirculation tank builds up residue, and eventually the floats stick, which causes false alarms and a maintenance shut down. Ideally, I’d like a non-contact level sensor with relay outputs to mimic the float level switch points. That way, I don’t have to reconfigure the hardware or programming on the PLC.” For this reason, Flowline suggested our EchoPod multi-function ultrasonic level sensor which has four programmable relays. The ultrasonic sensor provides reliable level switch inputs to the PLC, which monitors the recirculation tank and controls the parts wash cycle. Flowline is reliable level switching. |