|

|

|

|

|

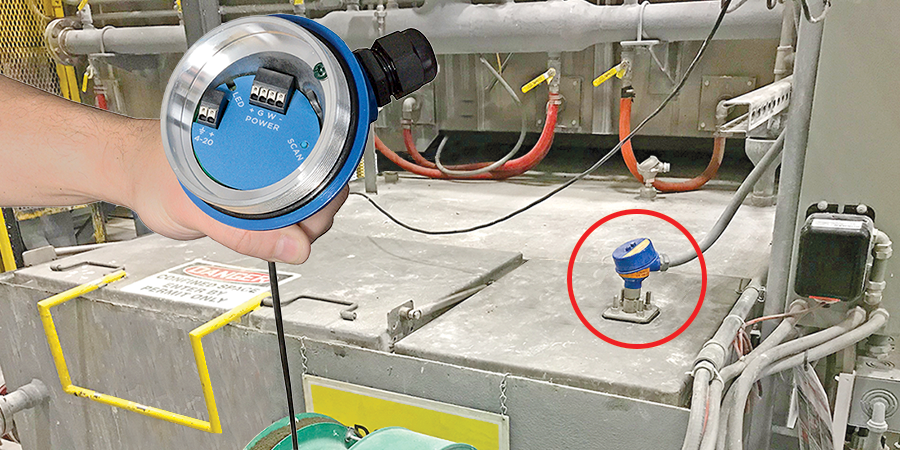

When an Ohio metal finishing and lamination manufacturer needed reliable level measurement of their chrome batch, plating and rinse tanks, they turned to Flowline. The company surface treats aluminum roll stock to customer specifications, and finish process quality and efficiency is vital to their business. The process is mildly corrosive, hot, condensing and foaming, and their operators had experienced ongoing problems with ultrasonic sensors. For this reason, Flowline suggested the use of our guided wave liquid level sensors that are unaffected by such process variables. Each guided wave sensor provides continuous level data to the PLC, which in turn, controls the batching, filling and emptying of the tanks. Flowline is reliable level measurement. |