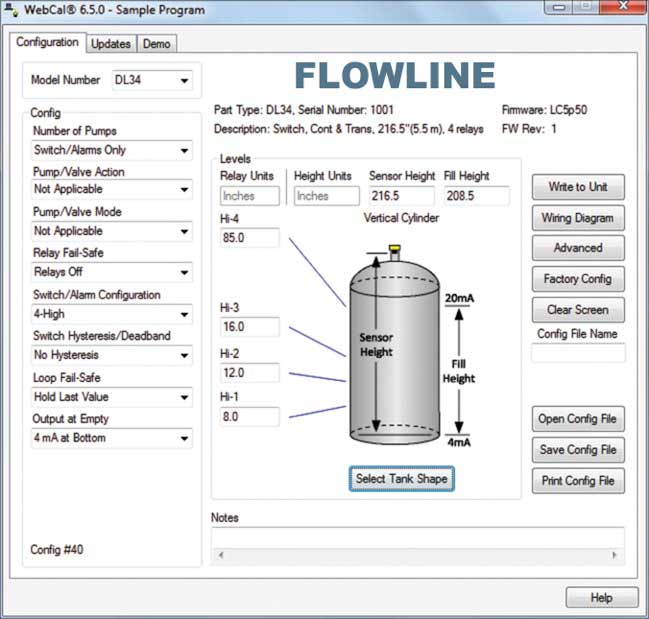

WebCal Software

The PC utility allows you to easily configure and test compatible level sensors to your requirements.

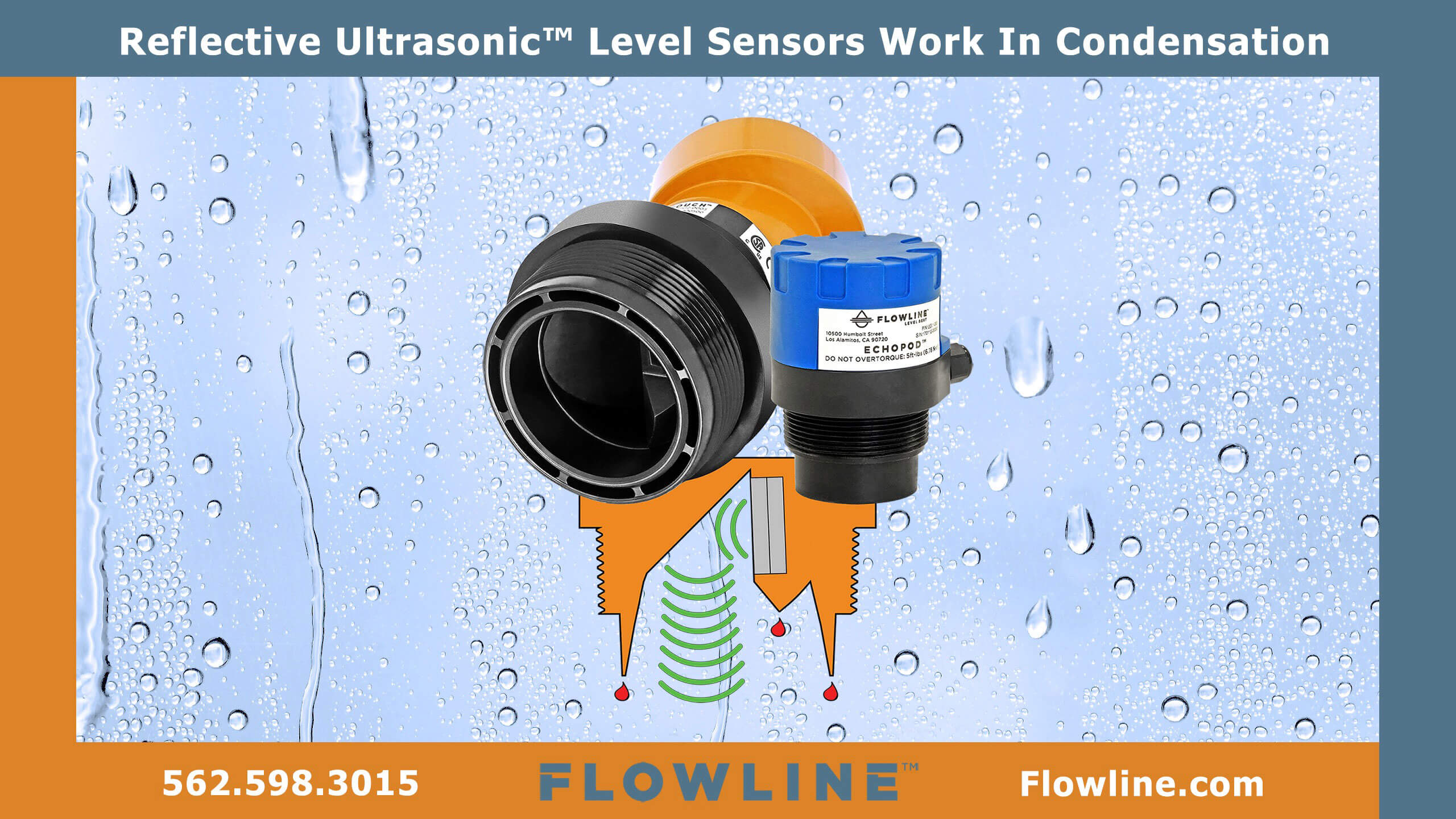

Technology Videos

Watch and learn about our 80 GHz radar, reflective ultrasonic and guided wave level sensor technologies.

Level Brochure

Request your free copy of our liquid and solids level measurement and control solutions brochure.